PUMPS

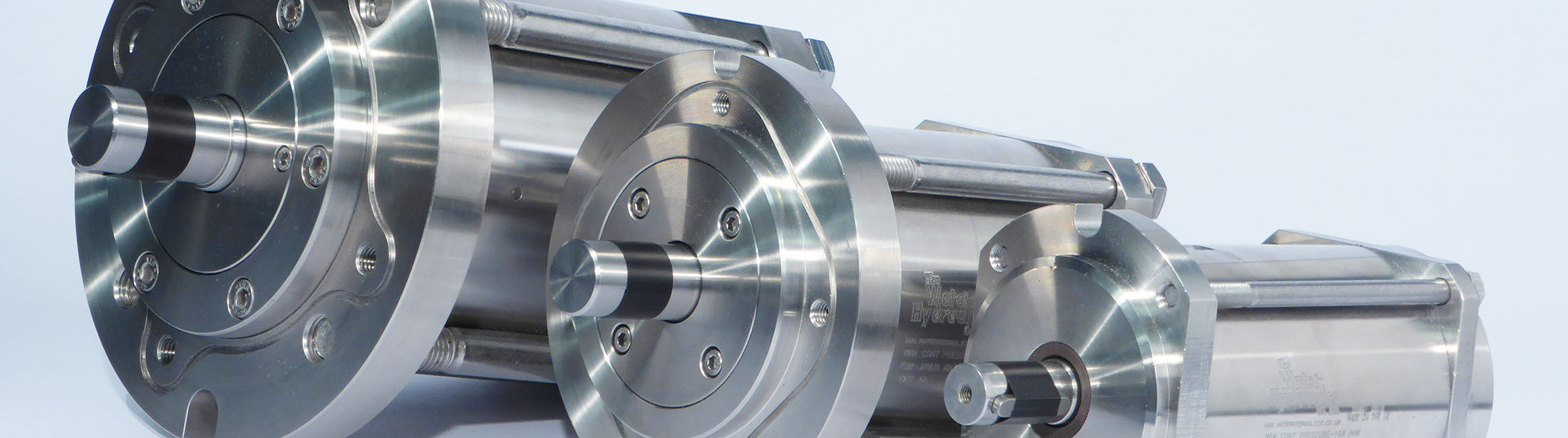

Totally oil free, clean and completely safe for people, processes and products.

As a result of employing advanced materials, high velocity and loaded sliding surfaces can operate effectively with water as their only coolant/lubricant.

The potential for cross contamination of the system fluid or the lubricating oil is removed.

The result is an exceptionally small light weight product.

Each bearing employs a hard/soft interface that minimises vibration and ensures a low noise and high efficiency operation.

Manufactured in A.I.S.I. 316 stainless steel as standard the product offers excellent resistance to corrosive fluids.

The materials utilised internally can be selected to suit the most appropriate combinations for not just tap water but also sea water and various other fluids.

Minimal pulsation is experienced with these units due to the multiple piston design and the high operational speeds.

Accurate flow metering is simply achieved with the control of the output shaft speed.

Motor Pump Assemblies

A standard range of bell housing and couplings are available for connecting the pumps to the B5 electric motor flange.

The pumps are not capable of operating with induced axial or radial loads on the output shaft. Always adopt the use of a 3 part Gear style coupling where possible.

If the drive shaft/spigot location is within 0.05mm concentricity direct inline drive assemblies are permissible.

Variable Displacement Pump

Based on their P60 fixed displacement unit the new product operating as a pump will offer infinitely variable output upto a

maximum displacement of 73cc/rev producing upto 110l/min to a maximum pressure of 160 bar on a fixed speed 4 pole 50hz motor.

Upto this point the market requirement has been satisfied by the fixed displacement design but in the search for ever increasing

high energy efficient systems the variable unit allows a systems requirement to be matched exactly with the optimum power input.

Designed specifically for a new development by a Swiss company; out of Lausanne University who produce energy storage systems.

The units function as both a pump and a motor delivering high volumetric and torque efficient performance with closed loop control

via an integral electronic servo control valve.

The larger P180 225cc/rev unit we also be available later in the year boosting an impressive variable output upto a maximum power of 115kW.

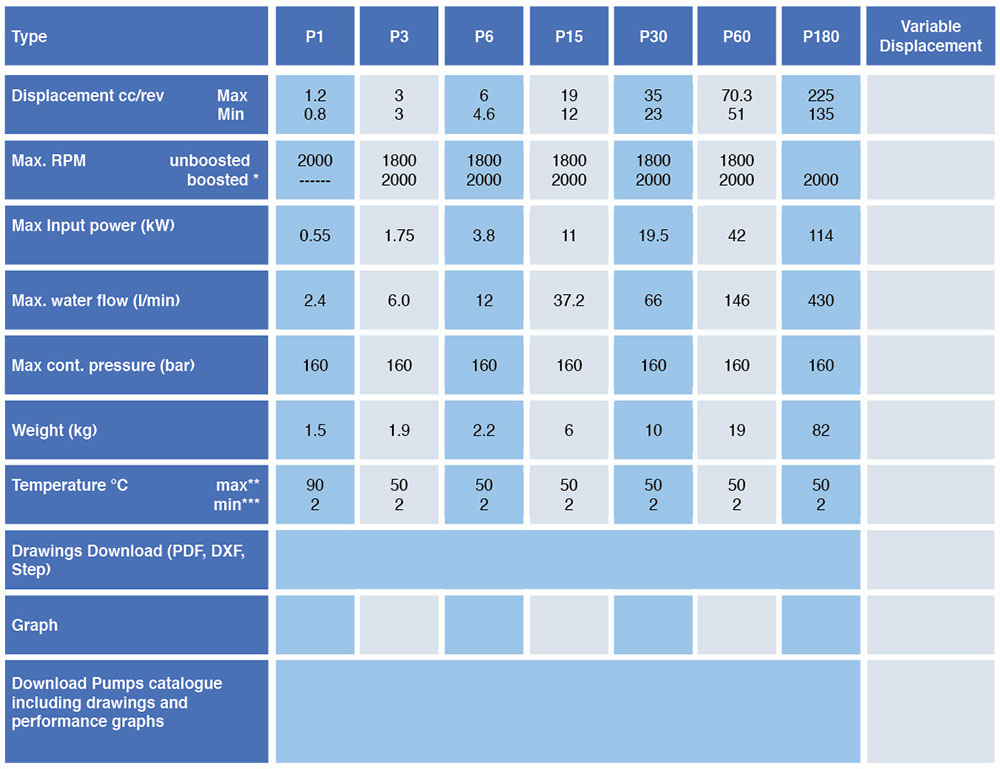

Temperature

The units will generate full performance from 2°C to 50°C. For temperatures below freezing an environmentally friendly antifreeze is available;

ask for the glycol data sheet. Operation above 50°C is possible, but the volumetric efficiency of the unit will be affected

consult TWHC and specify the maximum operating temperature.

Filters

All incoming water to the pumps must be pre-filtered to a nominal rating of 10µm (25µm absolute) with a

filter element rating of ß10 = 75 or better. Return line filtration is advisable on closed loop systems. High pressure filtration may also be considered.